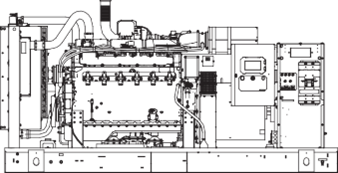

MG200 | 14.2L | 200 kW

INDUSTRIAL SPARK-IGNITED GENERATOR SET

EPA Certified Stationary Emergency and Non-Emergency

Standby Power Rating

200 kW, 250 kVA, 60 Hz

Demand Response Rating

200 kW, 250 kVA, 60 Hz

Prime Power Rating

180 kW, 225 kVA, 60 Hz

Codes and Standards

Not all codes and standards apply to all configurations. Contact factory for details.

UL2200, UL6200, UL1236, UL489

CSA C22.2, B149

M BS5514 and DIN 6271

SAE J1349

NFPA 37, 70, 99, 110

NEC700, 701, 702, 708

NEMA ICS10, MG1, 250, ICS6, AB1

ANSI C62.41

IBC 2009, CBC 2010, IBC 2012, ASCE 7-05, ASCE 7-10, ICC-ES AC-156 (2012)

Powering Ahead

Generac ensures superior quality by designing and manufacturing most of its generator components, such as alternators, enclosures, control systems and communications software. Generac also makes its own spark-ignited engines, and they can be found on every Generac gaseous-fueled generator. We engineer and manufacture them from the block up — all at our facilities throughout Wisconsin. Applying natural gas and LPfueled engines to generators requires advanced engineering expertise to ensure reliability, durability and necessary performance. By designing specifically for these dry, hotter-burning fuels, the engines last longer and require less maintenance. Building our own engines also means we control every step of the supply chain and delivery process, so you benefit from single-source responsibility.

Plus, Generac Industrial Power’s distribution network provides all parts and service so owners don’t have to deal with third-party suppliers. It all leads to a positive owner experience and higher confidence level. Generac spark-ignited engines give more options in commercial and industrial generator applications as well as extended run time from utility-supplied natural gas.

APPLICATION AND ENGINEERING DATA

ENGINE SPECIFICATIONS

General

| Make | Generac |

| Cylinder # | 6 |

| Type | In-line |

| Displacement - in³ (L) | 5.31 (135) |

| Bore: in (mm) | 5.31 (135) |

| Stroke: in (mm) | 6.50 (165) |

| Compression Ratio | 9.5:1 |

| Intake Air Method | Turbocharged/Aftercooled |

| Number of Main Bearings | 7 |

| Connecting Rods | Steel Alloy |

| Cylinder Head | Cast Iron |

| Cylinder Liners | Ductile Iron |

| Ignition | Electronic |

| Piston Type | Aluminum |

| Crankshaft Type | Ductile Iron |

| Lifter Type | Solid |

| Intake Valve Material | Special Heat-Resistant Steel |

| Exhaust Valve Material | High Temperature Steel Alloy |

| Hardened Valve Seats | High Temperature Steel Alloy |

Lubrication System

| Oil Pump | Gear |

| Oil Filter Type | Full-Flow with Cartridge |

| Engine Oil Capacity: qt (L) | 36.2 (34.3) |

Cooling System

| Cooling System Type | Pressurized Closed Recovery |

| Fan Type | Pusher |

| Fan Speed (RPM) | 1,894 |

| Fan Diameter - in (mm) | 30 (762) |

Fuel System

| Fuel Type | Natural Gas |

| Carburetor | Down Draft |

| Secondary Fuel Regulator | Standard |

| Fuel Shut Off Solenoid | Standard |

| Operating Fuel Pressure - in H2O (kPa) | 7 - 11 (1.7 - 2.7) |

Engine Electrical System

| System Voltage | 24 VDC |

| Battery Charger Alternator | 57.5 A |

| Battery Size | See Battery Index 0161970SBY |

| Battery Voltage | (2) - 12 VDC |

| Ground Polarity | Negative (-) |

Engine Governing

| Governor | Electronic |

| Frequency Regulation (Steady State) | ±0.25% |

ALTERNATOR SPECIFICATIONS

| Standard Model | K0200124Y21 |

| Poles | 4 |

| Field Type | Revolving |

| Insulation Class - Rotor | H |

| Insulation Class - Stator | H |

| Total Harmonic Distortion | <5% |

| Telephone Interference Factor (TIF) | <50 |

| Standard Excitation | Permanent Magnet |

| Bearings | Single Sealed Ball |

| Coupling | Direct via Flexible Disc |

| Prototype Short Circuit Test | Yes |

| Voltage Regulator Type | Full Digital |

| Number of Sensed Phases | All |

| Regulation Accuracy (Steady State) | ±0.25% |

OPERATING DATA

POWER RATINGS – NATURAL GAS

General

| Three-Phase 120/208 VAC @0.8pf | 200 kW / 250 kVA | Amps: 695 |

| Three-Phase 120/208 VAC @0.8pf | 180 kW / 225 kVA | Amps: 625 |

| Three-Phase 277/480 VAC @0.8pf | 200 kW / 250 kVA | Amps: 241 |

| Three-Phase 277/480 VAC @0.8pf | 180 kW / 225 kVA | Amps: 217 |

| Three-Phase 346/600 VAC @0.8pf | 200 kW / 250 kVA | Amps: 241 |

| Three-Phase 346/600 VAC @0.8pf | 180 kW / 225 kVA | Amps: 217 |

MOTOR STARTING CAPABILITIES (SKVA)

| 277/480 VAC | 30% | K0200124Y21 | 478 |

| 120/208 VAC | 30% | K0200124Y21 | 361 |

| K0250124Y21 | 630 | K0250124Y21 | 506 |

| K0300124Y21 | 790 | K0300124Y21 | 609 |

FUEL CONSUMPTION RATES*

| Percent Load | Standby/Demand Response | Prime |

|---|---|---|

| 25% | 960 (27.2) | 900 (25.5) |

| 50% | 1,440 (40.8) | 1,320 (37.4) |

| 75% | 1,980 (56.1) | 1,800 (51.0) |

| 100% | 2,460 (69.7) | 2,280 (64.6) |

COOLING

| Unit | Standby/Demand Response | Prime | |

|---|---|---|---|

| Air Flow (Fan Air Flow Across Radiator) | scfm (m³/min) | 9,162 (259.4) | 9,162 (259.4) |

| Coolant Flow | gpm (Lpm) | 90 (340.7) | 90 (340.7) |

| Coolant System Capacity | gal (L) | 11 (39.7) | 11 (39.7) |

| Maximum Operating Ambient Temperature | °F (°C) | 122 (50) | 122 (50) |

| Maximum Operating Ambient Temperature (Before Derate) | See Bulletin No. 0199270SSD | See Bulletin No. 0199270SSD | |

| Maximum Additional Radiator Backpressure | in H2O (kPa) | 0.5 (0.12) | 0.5 (0.12) |

COMBUSTION AIR REQUIREMENTS

| Standby/Demand Response | Prime | |

|---|---|---|

| Flow at Rated Power | 390 scfm — (11.0 m³/min) | 362 scfm — (10.3 m³/min) |

ENGINE

| Unit | Standby/Demand Response | Prime | |

|---|---|---|---|

| Rated Engine Speed | RPM | 1,800 | 1,800 |

| Horsepower at Rated kW** | hp | 304 | 274 |

| Piston Speed | ft/min (m/min) | 1,950 (594) | 1,950 (594) |

| BMEP | psi (kPa) | 155 (1,065) | 139 (959) |

EXHAUST

| Unit | Standby/Demand Response | Prime | |

|---|---|---|---|

| Exhaust Flow (Rated Output) | scfm (m³/min) | 1,327 (38) | 1,213 (34) |

| Maximum Allowable Back Pressure (Post Silencer) | in Hg (kPa) | 0.75 (2.54) | 0.75 (2.54) |

| Exhaust Temp (Rated Output - Post Silencer) | °F (°C) | 1,378 (748) | 1,350 (732) |

STANDARD FEATURES

- Oil Drain Extension

- Air Cleaner

- Fan Guard

- Stainless Steel Flexible Exhaust Connection

- Factory Filled Oil and Coolant

- Radiator Duct Adapter (Open Set Only)

- Critical Silencer (Open Set Only)

- Oil Temperature Indication and Alarm

- NPT Fuel Connection on Frame

- Primary and Secondary Fuel Shutoff

- Closed Coolant Recovery System

- UV/Ozone Resistant Hoses

- Factory-Installed Radiator

- 50/50 Ethylene Glycol Antifreeze

- Radiator Drain Extension

ALTERNATOR SYSTEM

- Battery Charging Alternator

- Battery Cables

- Battery Tray

- Rubber-Booted Engine Electrical Connections

- Solenoid Activated Starter Motor

ALTERNATOR SYSTEM

- UL2200 GENprotect™

- Motorized Main Line Circuit Breaker

- Class H Insulation Material

- 2/3 Pitch

- Skewed Stator

- Permanent Magnet Excitation

- Sealed Bearings

- Amortisseur Winding

- Full Load Capacity Alternator

GENERATOR SET

- Spring Isolators Under Frame

- Wrapped Exhaust Piping

- Separation of Circuits – High/Low Voltage

- Separation of Circuits – Multiple Breakers

- Standard Factory Testing

- 2 Year Limited Warranty (Standby and Demand Response Rated Units)

- 1 Year Limited Warranty (Prime Rated Units)

- Silencer Mounted in the Discharge Hood (Enclosed Units Only)

ENCLOSURE (If Selected)

- Rust-Proof Fasteners with Nylon Washers to Protect Finish

- High Performance Sound-Absorbing Material (Sound Attenuated Enclosures)

- Gasketed Doors

- Upward Facing Discharge Hood (Radiator and Exhaust)

- Stainless Steel Lift Off Door Hinges

- Stainless Steel Lockable Handles

- RhinoCoat™ - Textured Polyester Powder Coat Paint

CONTROL SYSTEM

- Remote Wireless Software Update Capable

- BMS and Remote Telemetry

- Built-In Programmable Logic Eliminates the Need for External Controllers Under Most Conditions

- Ethernet Based Communications Between Generators

- Programmable I/O Channel Properties

- Built-In Diagnostics

- Arc Flash Maintenance Mode (When Correctly Equipped)

Power Zone® Pro Sync Controller

- NFPA 110 Level 1 Compliant

- Engine Protective Functions

- Alternator Protective Functions

- Digital Engine Governor Control

- Digital Voltage Regulator

- Multiple Programmable Inputs and Outputs

- Remote Display Capability

- Remote Communication via Modbus® RTU, Modbus TCP/IP, and Ethernet 10/100

- Alarm and Event Logging with Real Time Stamping

- Expandable Analog and Digital Inputs and Outputs

Alarms and Warnings

- Low Oil Pressure

- Low Coolant Level

- High/Low Coolant Temperature

- Sensor Failure

- Oil Temperature

- Over/Under Speed

- Over/Under Voltage

- Over/Under Frequency

- Over/Under Current

- Over Load

- High/Low Battery Voltage

- Battery Charger Current

- Phase to Phase and Phase to Neutral Short Circuits (I2T Algorithm)

7 Inch Color Touch Screen Display

- Resistive Color Touch Screen

- Sunlight Readable (1400 NITS)

- Easily Identifiable Icons

- Multi-Lingual

- On Screen Editable Parameters

- Key Function Monitoring

- Three Phase Voltage, Amperage, kW, kVA, and kVAr

- Selectable Line to Line or Line to Neutral Measurements

- Frequency

- Engine Speed

- Engine Coolant Temperature

- Engine Oil Pressure

- Engine Oil Temperature

- Battery Voltage

- Hourmeter

- Warning and Alarm Indication

- Diagnostics

- Maintenance Events/Information

PARALLELING CONTROLS

- Paralleling Control (Synchronizing)

- Reverse Power

- Loss of Synchronization Between Gensets

- Load and VAR Sharing

ENGINEERED OPTIONS

CONTROL SYSTEM

- Battery Disconnect Switch

GENERATOR SET

- Special Testing

- Battery Box

ALTERNATOR SYSTEM

- 2nd Breaker System

ENGINE SYSTEM

- Fluid Containment Pans

CONFIGURABLE OPTIONS

ENGINE SYSTEM

- Engine Coolant Heater

- Baseframe Cover/Rodent Guard

- Two Stage Air Cleaner

- Oil Heater

- Air Filter Restriction Indicator

- Radiator Stone Guard (Open Set Only)

- Level 1 Fan and Belt Guards (Enclosed Units Only)

ALTERNATOR SYSTEM

- Alternator Upsizing

- Anti-Condensation Heater

- Tropical Coating

ELECTRICAL SYSTEM

- 10A UL Listed Battery Charger

- Battery Warmer

- Main Line Circuit Breaker

- Electronic Trip Breakers

GENERATOR SET

- Demand Response Rating

- Extended Factory Testing

- 12 Position Load Center

- Vapor Recovery Heater

CONTROL SYSTEM

- NFPA 110 Level 1 Compliant 21-Light Remote Annunciator

- Remote Output Relays (8 or 16)

- Remote E-Stop (Break Glass-Type, Surface Mount)

- Remote E-Stop (Red Mushroom-Type, Surface Mount)

- Remote E-Stop (Red Mushroom-Type, Flush Mount)

- 10A Engine Run Relay

- Ground Fault Annunciator

- 120V GFCI and 240V Outlets

- Damper Alarm Contacts (With Motorized Dampers Only)

- 100 dB Alarm Horn

- Permissive/Load Shed Module

ENCLOSURE

- Weather Protected Enclosure

- Level 1 Sound Attenuated

- Level 2 Sound Attenuated

- Level 2 Sound Attenuated with Motorized Dampers

- Steel Enclosure

- Aluminum Enclosure

- Damper Alarm (with Motorized Dampers Only)

- Up to 200 MPH Wind Load Rating (Contact Factory for Availability)

- AC/DC Enclosure Lighting Kit

- Enclosure Heaters (with Motorized Dampers Only)

- IBC Certification

- Door Open Alarm Switch

WARRANTY (Standby Gensets Only)

- 2 Year Extended Limited Warranty

- 5 Year Limited Warranty

- 5 Year Extended Limited Warranty

- 7 Year Extended Limited Warranty

- 10 Year Extended Limited Warranty

FUEL SYSTEM

- NPT Flexible Fuel Line