WPI delivers uptime™

Taking care of your equipment in the field is a WPI commitment. Our field service technicians are equipped with the resources, skills, and training. WPI utilizes Service Pro® to optimize technicians’ time, communication capabilities, and high-quality, consistent construction machinery services. That’s how we deliver uptime.

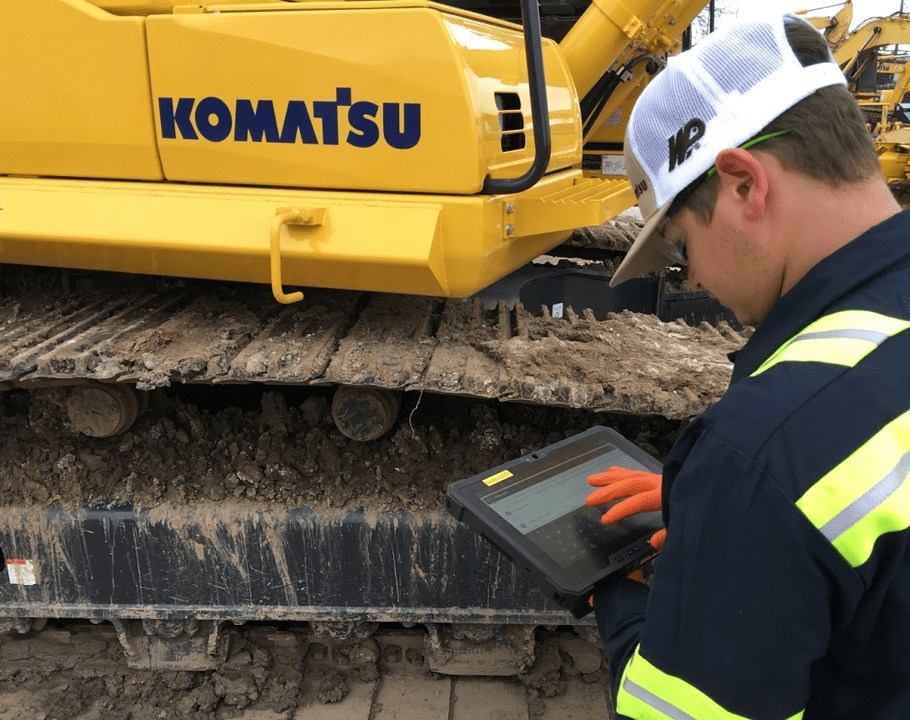

Field Services

Our service technicians are ready to assist you at the job site with diagnostic tools and the knowledge to increase uptime. Efficiency in field service is crucial. To ensure high-quality, consistent service, WPI utilizes Service Pro®. Service Pro reports provide our customers status of their jobs with detailed reports, including onsite pictures. Our construction machinery services technicians are empowered to provide responsive, proactive service. WPI’s back-office teams have access to the same information as the field technicians – everyone is fully informed.

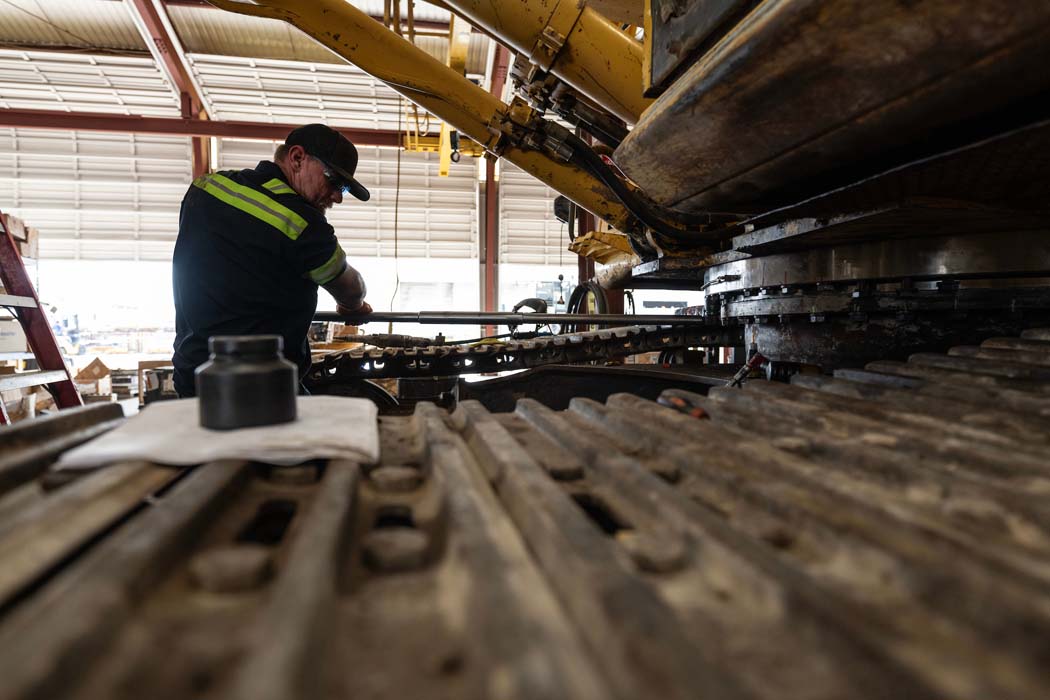

Shop Services

WPI shop facilities have the latest tooling and technology to handle your repairs. WPI maintains A local presence across Texas and Louisiana, offering fast, convenient support for all your equipment needs. Each facility offers an extensive inventory of parts and A broad range of construction machinery services performed by factory-certified technicians. Our Product Support Representatives (PSR) are readily available to assist, educate, troubleshoot, look for patterns, and go above and beyond to help identify and solve problems. From undercarriage evaluation to problem resolution, your local PSR will work directly with you to support your equipment across our product lines.

WPI Products Support Team

Our Product Support Team’s goal is to be there for YOU. Reach out to them; they are standing by.

Preventive Maintenance – Strategies to boost efficiency

WPI offers the most comprehensive planned maintenance program for earth moving, recycling, forestry, and mining solutions to keep your equipment running optimally, often called Preventive or Predictive maintenance. This construction machinery services program allows you to detect problems before breakdowns occur. For construction fleets, our experts recommend using an oil analysis program to identify the current health of your products and extend drain intervals where possible, keeping your fleet running smoothly and minimizing unnecessary downtime.

Due to our close relationships with our equipment partners and extensive knowledge of industry standards, our program helps you get the most value out of your data, from reliable predictive information to recommended action plans and onsite support from our technicians.

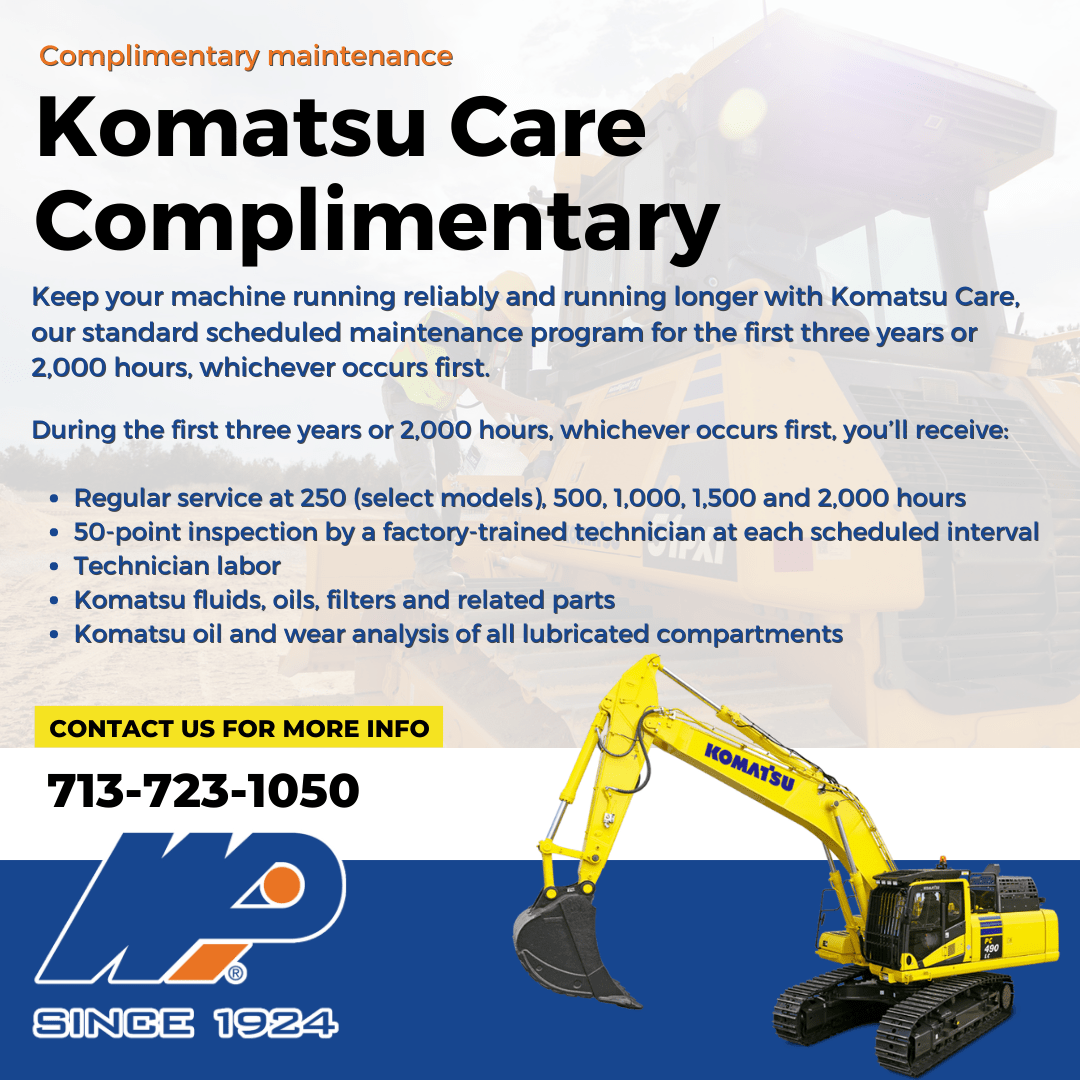

Komatsu Care

No one knows your machine better. To help extend the life of your investment, Komatsu offers inclusive coverage options beyond the standard warranty. Whether you want to increase machine resale value or protect your investment from everyday wear, WPI will help you decide which option best fits your needs. Experience the peace of mind that comes with Komatsu’s maintenance and repair support options.

Komatsu Oil & Wear Analysis (KOWA)

KOWA has been an established Komatsu program for more than 40 years. The company’s construction and mining customers have used KOWA as an effective preventive maintenance and diagnostic tool through their North American Komatsu distributors. Analyzing engine oil and other fluids is an effective way to identify the health of a machine’s engine and powertrain to make informed repair and maintenance decisions.

Proper oil and fluid analysis can extend component life, identify minor problems before they become major failures, and help customers make informed reselling and purchasing decisions. KOWA’s testing facilities are ISO-accredited to ensure high-level accuracy. To eliminate maintenance guesswork, oil analysis results are compared to Komatsu guidelines. The program features an online web portal for customers and dealers to view oil analysis results within minutes once testing has been completed.

Real-Time Fleet Telematics

Komtrax GPS, provided at no additional charge, is full-service monitoring on Komatsu equipment and free basic construction machinery services monitoring on all other brands. Telematics is an interdisciplinary field encompassing telecommunications, road transportation, vehicular technologies, road safety, computer science, electrical engineering, and an essential part of real-time fleet management.

Available data points (Data varies by OEM and machine application)

- Equipment header

- Last known location

- Cumulative operating hours

- Cumulative fuel used

- Fuel used - previous 24 hours

- Cumulative distance traveled

- Cumulative idle hours

- Fuel remaining ratio

- DEF remaining ratio

- Engine status

- Cumulative power take-off hours

- Average daily engine load factor - previous 24 hours

- Peak daily maximum speed - last 24 hours

- Cumulative load count

- Cumulative payload total

- Cumulative non-productive regeneration hours

- Cumulative non-productive idle hours

Undercarriage Service

Avoid costly repairs by early detection of wear & misalignment. From inspection, pin, and bushing turn to a complete inventory of replacement parts, we’ll keep you tracking. If you own or operate heavy equipment that depends on tracks, you know that your undercarriage is critical for performance. Crawling equipment is complex and built to withstand harsh conditions. However, no equipment is impervious to wear and misalignment. Your effort on undercarriage maintenance will pay off in extended component life and continued working time. Undercarriage maintenance can account for 50% of your equipment maintenance budget. Proper undercarriage preventative maintenance is essential to get the most out of your equipment investment.

Welding and Fabrication Services

As part of our construction machinery services, WPI offers fabrication for customization, relief for buckets and blades, and line boring to maximize the life span of wear points.

Welding

Let our welding shop repair your equipment pieces or create new parts. We use two welding techniques:

- MIG and stick welding - Stick and MIG welding works well for large and small projects. Our field crew can bring these welding techniques to your site for quick repairs.

- TIG welding - TIG welding suits metals such as copper, aluminum, and titanium. It can also weld two different metals together for specialized components.

Machining

The WPI machining team shapes a variety of metals into long-lasting components. We have machining equipment such as:

- Milling machines - Our milling machines shape parts and metal by moving a cutter toward the workpiece. They can surface cylinder heads, engine blocks, and manifolds.

- Line boring machines - In-shop and portable line boring machines can restore your parts to their original dimensions. These machines can handle diameters ranging from 1 inch to 24 inches.

Training and Technical Support

Part of WPI’s commitment to customer service includes providing training, education, and factory certification programs. Training courses are available at your location, the job site, or VR for the latest technologies in equipment, helping you protect your investment and improve productivity by giving your employees the skills they need to keep the job moving.